Hardening of Scissors

Induction Hardening of Scissors

The production of hardware tools requires heat treatment. The heat treatment of ordinary hardware tools includes: annealing, normalizing, quenching and tempering, and heat treatment of surface hardware tools includes surface quenching and chemical heat treatment of hardware tools.

At present, the commonly used hardware tools, after the metal parts are processed and formed, are generally subjected to heat treatment to improve their performance, such as improving their surface hardness and service life, and the quenching process is a common method used to improve the surface hardness of metal parts in heat treatment. step. Therefore, hardware tools such as hammers, wrenches, scissors, etc. also need to be heat treated, in order to strengthen the hardness of the surface of the hardware tools.

Scissor quenching is to rapidly heat the scissors to the required temperature, and then quickly put them in oil to quench and cool. In this way, the surface strength, hardness and wear resistance are improved, and good material properties are obtained. The material of the scissors is alloy tool steel, which requires high hardness and small deformation after quenching. Since the scissors are long and thin, it is easy to deform, which brings great challenges to the quenching of the scissors. To avoid deformation, it must be heated quickly to the desired temperature and cooled rapidly. Induction heating is widely used for scissor quenching due to its rapid heating advantage

If you need to harden your hardware tools, choose induction hardening equipment from TY Induction. TY Induction's hardening equipment uses induction heating technology to quench the surface of hardware tools. Working principle: The workpiece is placed in the inductor, and high-frequency or medium-frequency alternating current flows through the inductor to generate an alternating magnetic field and induce induction of the same frequency in the workpiece. Current, the distribution of this induced current in the workpiece is uneven, strong on the surface, but very weak in the interior, close to 0 in the center, using this skin effect, the surface of the workpiece can be rapidly heated, within a few seconds The surface temperature rises to 800-1000ºC, while the core temperature rises very little. After the workpiece is rapidly heated, the automatic water spray device starts to rapidly cool the workpiece and complete the entire quenching process of the workpiece.

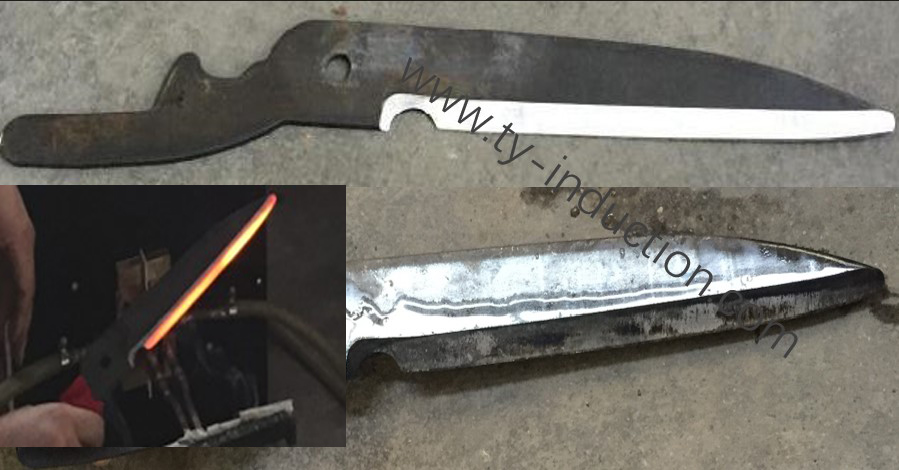

Photos

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000

HOT NEWS

High-quality Anchor Chains Induction Hardening and Tempering

January 03, 2025

Differences between Induction Heating of Austenite and Martensite Materials

December 25, 2024

The Role of Induction Forging in High-Strength Motorcycle Parts

December 23, 2024