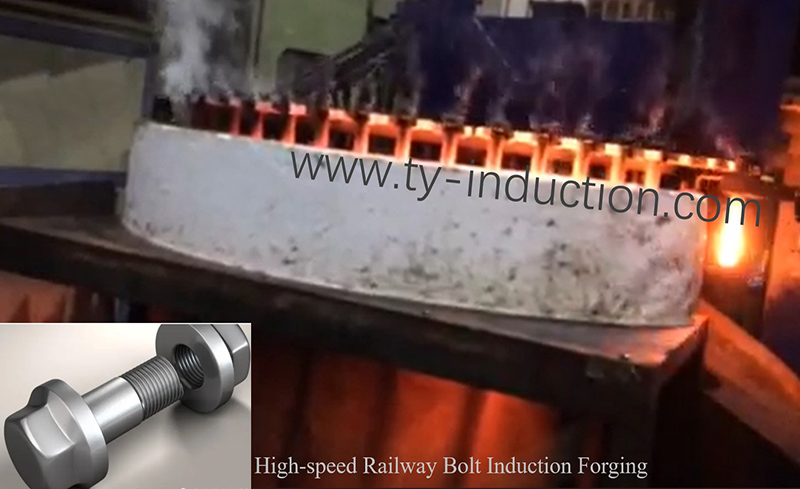

High-speed Rail Bolts Forging

Compared with ordinary trains, high-speed trains have higher requirements for driving safety, which requires more reliable bolts that can effectively prevent falling off. Therefore, the forging requirements for high-speed rail bolts are also extremely high, and Induction Heating can ensure the forging quality of high-speed rail bolts.

Compared with ordinary trains, high-speed trains have higher requirements for driving safety, which requires more reliable bolts that can effectively prevent falling off. Therefore, the forging requirements for high-speed rail bolts are also extremely high, and Induction Heating can ensure the forging quality of high-speed rail bolts.

Since the hot forging process is carried out at high temperature, High-speed Rail Bolts Forging by induction heating / Induction Forging has the following advantages:

l The induction heating temperature can be controlled.

l Forgings at high temperature have good plasticity

l Low deformation resistance and easy to form

l Hot forging is suitable for various materials

l Especially suitable for processing large size bolts / nuts and special-shaped parts

l Hot forging is especially good for extra-long and extra-short bolts

l Hot forging avoids the problems of difficult forging, easy cracking and low yield of cold heading of alloy steel and stainless steel.

l Hot forging has good forming performance and small forging force.

Photos

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000

HOT NEWS

High-quality Anchor Chains Induction Hardening and Tempering

January 03, 2025

Differences between Induction Heating of Austenite and Martensite Materials

December 25, 2024

The Role of Induction Forging in High-Strength Motorcycle Parts

December 23, 2024