Induction Heating's Green Benefits In Automotive Manufacturing

December 13, 2023

Induction heating is a green and sustainable heating method that offers a number of benefits for manufacturing. It is more efficient, produces fewer emissions, and improves air quality. Induction heating systems are also safer and quieter than traditional heating methods.

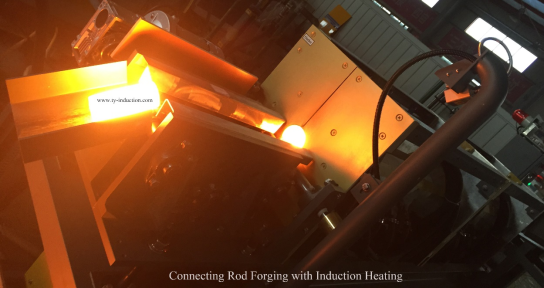

Induction heating plays a pivotal role in lessening the environmental footprint within the automotive manufacturing sector. It's extensively employed to heat metal components for various processes like forging, heat treating, brazing, tempering, shrink fitting and annealing. Traditionally, these operations relied on gas-fired or resistant electric furnaces. But the advent of induction heating brings significant advantages in terms of efficiency and emission reductions.

Consequently, numerous automotive manufacturers are transitioning to induction heating methods to curtail their environmental impact and foster sustainable practices in their production processes.

Induction heating stands out as an ideal solution for high-volume applications requiring consistent repeatability, particularly in the automotive industry where its use is widespread. Exploring the advantages of employing induction heating for automotive applications reveals several key benefits:

Axle Housing Induction Forming

Induction heating enables the targeted heating of specific areas on metal parts, a critical requirement in various manufacturing processes like Forging, heat treatment, hardening, annealing, and brazing. This precision ensures accurate temperature control and uniform heat distribution, contributing to enhanced quality standards.

The swiftness of induction heating accelerates production rates significantly. For instance, it can swiftly raise the temperature of components such as a camshaft gear from room temperature to the desired level within minutes, thereby optimizing production efficiency.

The precise and rapid nature of induction heating aids in minimizing defects in metal parts. For example, heating a steering knuckle or upright without causing discoloration helps prevent corrosion, enhancing the overall durability and reliability of components.

Induction heating operates without an open flame, ensuring a flameless process in the work environment. This inherent safety feature distinguishes it from traditional heating methods like flame brazing or soldering, making it a safer alternative.

Being an energy-efficient process, induction heating relies on electricity instead of gas, resulting in lower emissions. Its instant on/off heating capability further contributes to reduced environmental impact compared to conventional heating methods, aligning with eco-friendly industrial practices.

In summary, the adoption of induction heating in automotive manufacturing not only improves production efficiency but also enhances product quality, safety, and environmental sustainability, making it a preferred choice for various heating applications within the industry.

Induction, as a non-contact heating method utilizing electromagnetic induction to generate heat in conductive objects, presents manifold advantages for manufacturers. Its efficiency and precision make it a preferred choice for diverse applications, encompassing forging, brazing, soldering, heat treatment, melting, bonding, preheating for welding, and even medical and food processing. Moreover, its environmentally friendly attributes position it as a more sustainable heating method compared to others commonly used in industrial settings.

Induction heating boasts exceptional efficiency, achieving energy transfer efficiencies of up to 90%. This high efficiency translates to lower energy usage compared to methods like gas heating, which typically operates at around 50% efficiency.

With no direct emissions such as carbon dioxide or nitrogen oxides, induction heating stands out as a cleaner and more eco-friendly heating method than those reliant on fossil fuels.

By producing no smoke or fumes, induction heating contributes to better workplace air quality, diminishing the risk of respiratory issues among employees.

Induction heating systems operate quietly, thus aiding in the reduction of noise pollution in both the workplace and its surrounding environment.

Compared to traditional heating methods, induction heating systems are safer due to the absence of open flames or hot surfaces, significantly lowering the risk of accidents or injuries for employees.

In summary, the environmental benefits of induction heating encompass reduced energy consumption, emissions, and noise pollution, along with improvements in air quality and workplace safety. These advantages position induction heating as a sustainable and prudent choice for various industrial applications.

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000