Induction Elbow Production

Elbow is a commonly used component for changing the direction of pipelines. This component is very commonly used in pipeline construction. Elbow has 180 degrees, 90 degrees and 45 degrees, etc. Depending on the material and pressure, there are several types of elbow production: hot pushing, stamping, extrusion and butt welding.

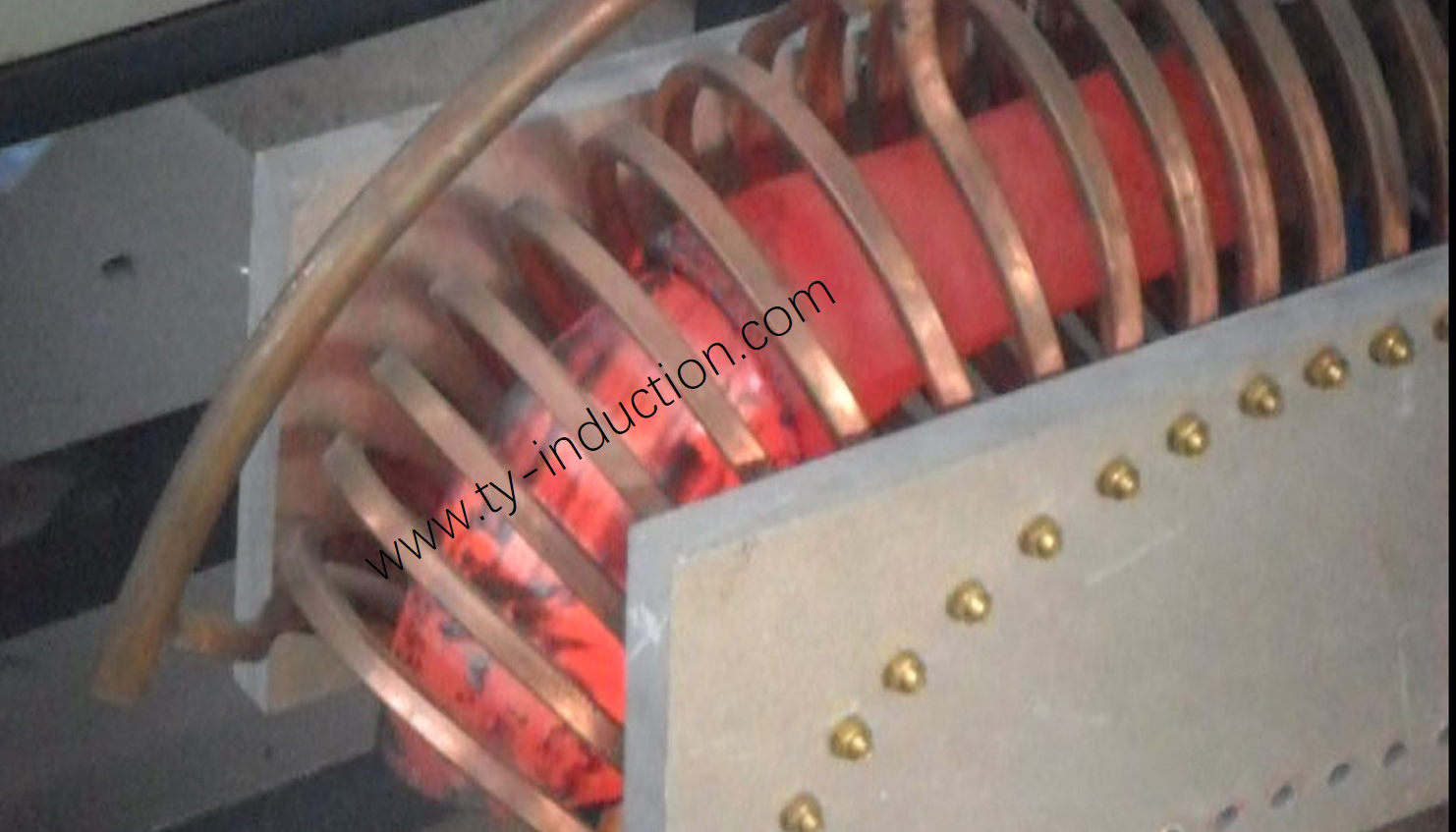

Hot pushing elbow forming is a method of bending elbows under high temperature conditions. Under special push, the push rod is penetrated by axial thrust, and the press-in of the tube causes the tube blank to undergo axial expansion and axial bending deformation. The smaller diameter pipe is pressed into the larger diameter elbow. Elbows making is a process of expanding and bending.

For seamless elbow production, hot pushing with induction heating is the first choice. Elbow Hot Pushing Machine is mainly composed of hydraulic pushing machinery, mandrel and heating equipment.

TY Induction’s Induction Elbow Machines have excellent design and advance technology. Induction Elbow Machines manufactured by TY Induction brings many benefits to manufacturers of seamless elbow.

l Good looking and uniform wall thickness of elbow

l Continuous production and mass production

l Low wall reduction rate

l Good quality elbow

l Can produce carbon steel, alloy steel and stainless-steel elbow

l Fast Induction heating for high productivity

l Full automation with PLC control and friendly HMI

l Easy operation and installation

l Low operating cost and environmentally friendly

Photos

Hot Products

Contact Us

Enquiry hotline:

+86 135 4128 7190

Email:

Address:

No.18,14th Floor, Building 2, No. 169 Zhongli Road, Banzhuyuan Subdistrict, Xindu District, Chengdu, Sichuan, China, Code:610000

HOT NEWS

High-quality Anchor Chains Induction Hardening and Tempering

January 03, 2025

Differences between Induction Heating of Austenite and Martensite Materials

December 25, 2024

The Role of Induction Forging in High-Strength Motorcycle Parts

December 23, 2024